-

136+ Exporting countries

-

1660m2 Factory area

-

3000+ Enterprise employees

-

378+ Partners

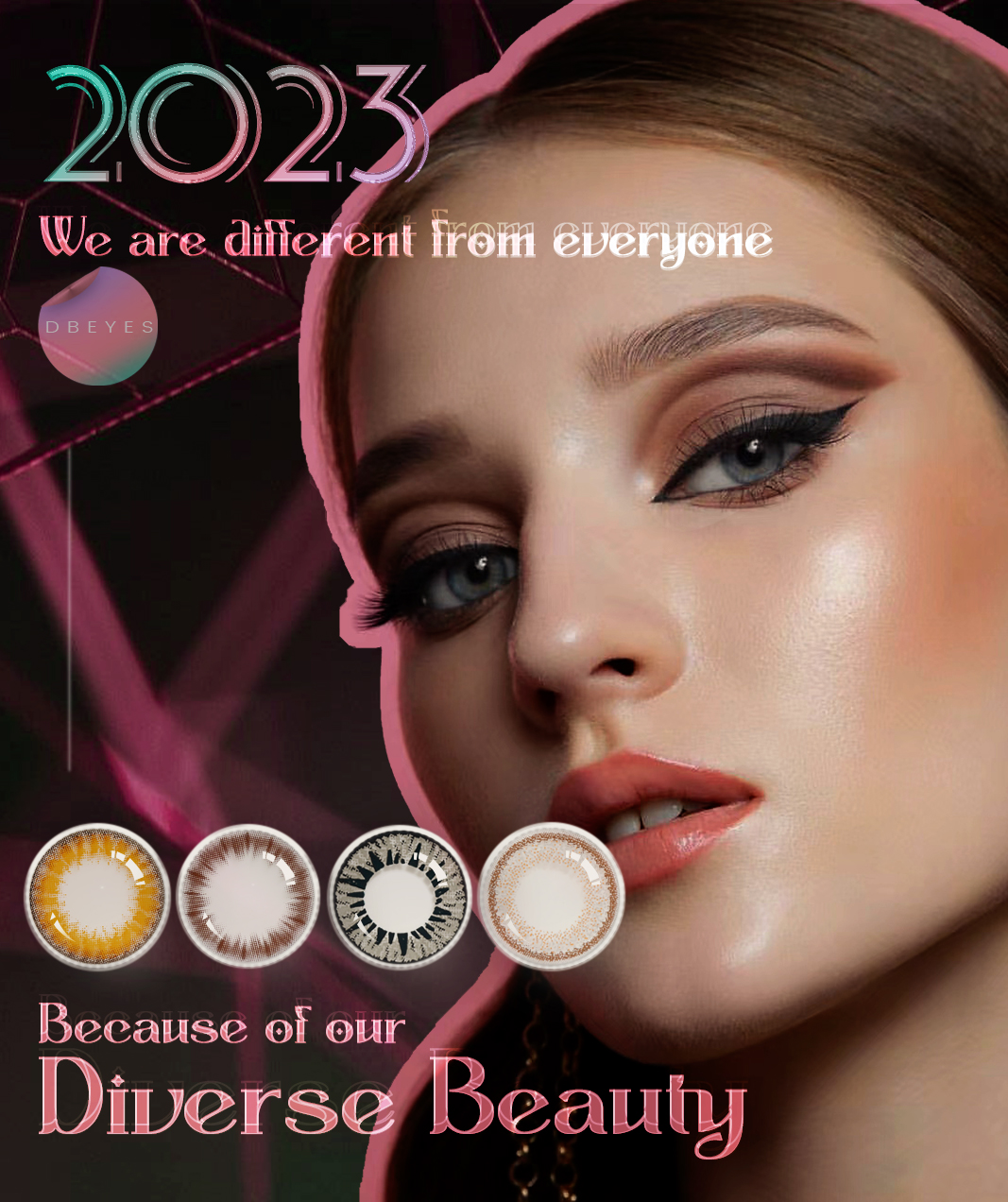

Brand story

Welcome to our enterprise

Wherever you are from, whatever identity you represent, your beauty should be seen, DB color contact lenses spread the energy you need for your presence. Let’s start your eye beauty journey with DB. We launched DB with 10 years experience of the sale and production of color contact lens we have gained.

ENTERPRISE ADVANTAGE

Welcome to our enterprise

Promote the development of

production and operation

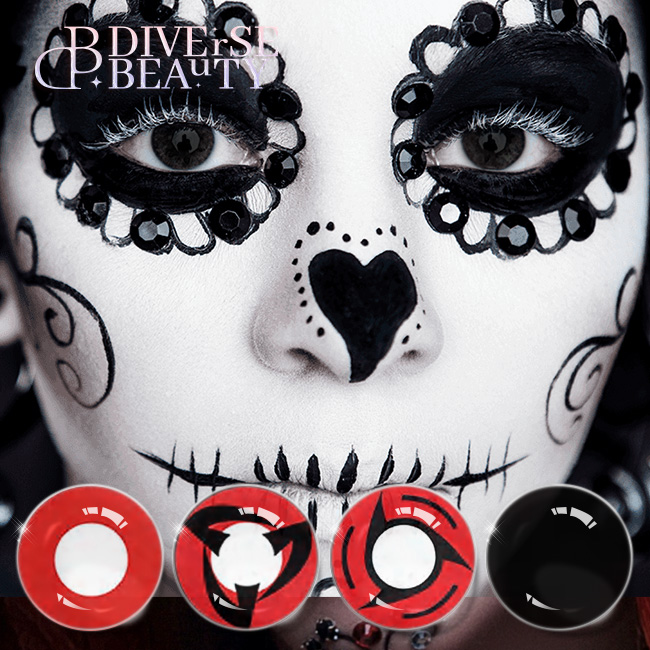

Our products

We provide you with the best quality products

Factory introduction

Introduce our factory to you by video

DB Station-OEM SERVICE

HOW TO WORK WITH US

Service Scope

Covering 70+ countries and regions worldwide

Camille come from france

Camille

come from france

In the romantic capital of France, Camille is preparing an exhibition of her paintings. The eye cannot lose its colored contact lenses, she says, just as a painting cannot lose its paint

Misharova from Egypt

Tassos

Come From The Lower Nile Country Of Egypt

Who is our faithful companion,said that the local condition sare not very good, the girls are mostly Muslim and they have to wear the veil all the time.contact lenses are their bestmakeup partner right now.

Misharova from AU

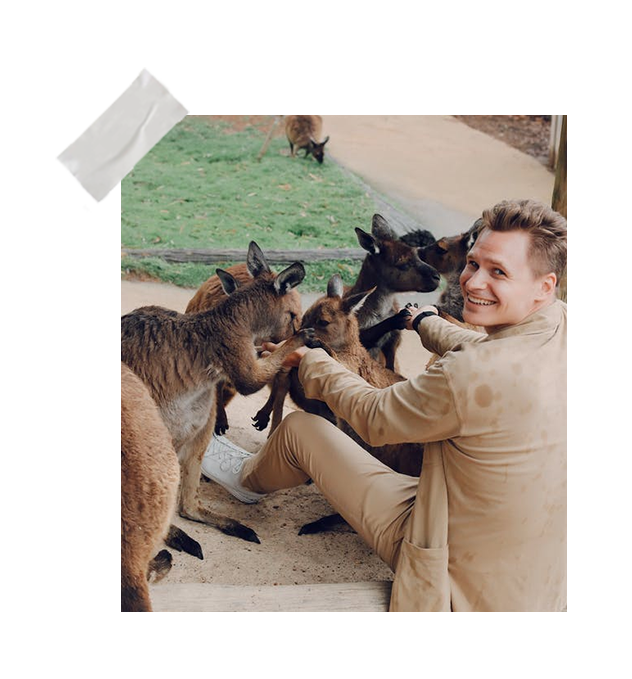

DAVID

COME FROM ANGLO-AUSTRALIAN

A man who loves photography and nature. His country has some special animals, such as kangaroos and koalas which are just like our giant pandas, very interesting and lovely. This is the feedback of nature to us

he come from Saudi Arabia

MISHAROVA

COME FROM RUSSIA

our little friend who already owns her cos shop and really enjoys cosplay. She is very satisfied with our products since our long-term cooperation.

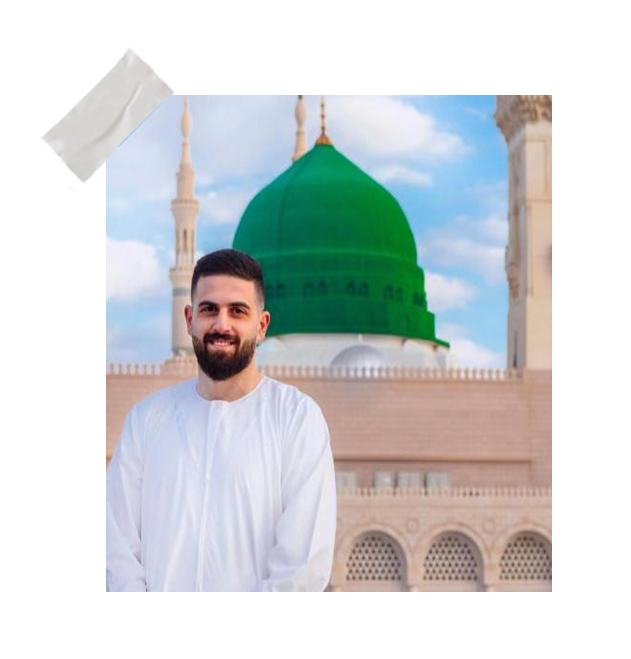

he come from Saudi Arabia

he

come from Saudi Arabia

This is her wife took a picture of him, because her husband's support, so her wife has their own contact lens store in the local and earn a lot of money, the photo of him smiling more sunshine

Marry come from US

Marry

come from US

Marry loves sports and has a tennis match next week. She says wearing contact lenses will make her more energetic on the court, and she believes he will win the championship

LUCY COME FROM CANADA

LUCY

COME FROM CANADA

An elegant North American woman. She is a pretty mother who is fond of doing makeup and recognizes our products as well. She often says that eyes are the window of the soul, and cosmetic contact lenses are very important to her

ELENA COME FROM BRAZIL

ELENA

COME FROM BRAZIL

A doctor in biology, she often works and does not pay much attention to her appearance,she said Brazil has a lot of male to female ratio,"we have a lot of beautiful girls, but few boys."

she come from Peru

she

come from Peru

This is our Peruvian client, she loves to travel and being in nature makes her feel the true meaning of life

Company Development

We provide you with the best quality products

Get Free Samples

Inquiries about products or prices, please leave your contact information to us and

we will contact you within 12 hours